The Alderson® sanding machines have been designed to be used in conjunction with water. It is the water that eliminates the heat build up causing blistered substrate. After repainting these blisters “pop” through damaging the newly coated paint. The only solution from there is a full paint strip. The use of water eliminates clogging and extends the life of the abrasive paper and so significantly reduces the time taken to prepare a surface for painting. The machines can also be used in wet conditions and it also eliminates the need for pre-sanding preparation such as water blasting and wiping the surface dry before dry sanding.

Features Summary

- Complies with AS/NZS 4361.2:2017 -The Standard for the removal of lead based paint, preferred method, 3.5.4 (a)

- Water prevents heat build-up causing substrate damage.

- Water reduces clogging.

- Water means no dust to interfere with washing on the line or cars parked nearby.

- Water means you don’t need to waterblast first.

- Water means that the abrasive discs last much longer – 4-5 discs per side for an average sized house without any lead paint.

- Water means surface preparation can be done on a rainy day.

- Water with the Alderson sander means that the slurry from lead based paints can easily be collected in the Alderson “Enviromat”. Tests show that 99.7% of lead waste is collected. See Information/ Data Sheet link below.

- No dust masks or vacuums required.

- No need for dust masks or vacuum bags.

- No expensive backing plates to replace.

- Used in conjunction with our “Enviromat” it is the safest system for the removal of lead based painted surfaces. There is no lead based dust and the sanded lead particles are safely collected in the Enviromat with the water passing through the mat. For this reason it is now the NZ Master Painters preferred system for the removal of lead based paint.

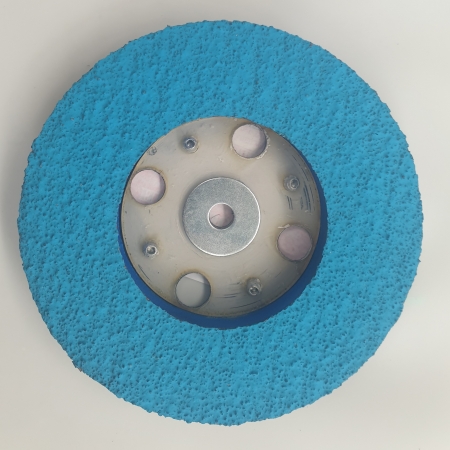

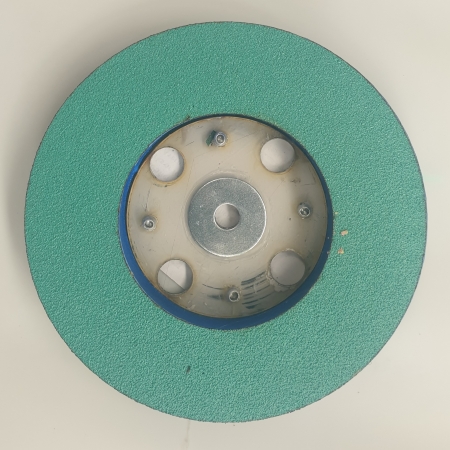

There is a range of different types of abrasive discs that can be used with the machine.

- Acrylic sanding discs

- Stripping and Finishing discs

- Other discs. Smaller 110mm disc and 80mm detailing discs

Where To Buy

Cost Comparisons

Generally speaking the Alderson sander is at least 6 to 8 times more productive than any other system.

The use of the water and the speed of the machine means that the sanding discs last a very long time.

For example an acrylic disc (Acrylic Prep & Finishing 60#) will sand between 40 and 60 square meters which means the abrasive cost for that disc is around 40 cents per square meter. However the real saving is in time. It takes just 6 seconds to sand a lineal meter compared with an average of 36 seconds for a dry sander.

With our flexible Heavy Duty stripping disc (HDSD) it will strip between 5 and 10 square meters of paint up to 12 or so layers thick. It is best to use this disc initially until you just start to see the timber coming through. Do not continue to strip until all the paint has been removed because you will also remove quite a bit of timber and leave deeper score marks in the timber. Stop when the timber shows through, then use the Light Duty Stripping (LDSD) disc to remove the remaining paint. This then needs to be followed up with a finishing disc, such as the Finishing 80# to remove the score marks. Once dry you may need to just touch up a few areas when you may have missed with a dry sander – you won’t need to dry sand the whole house. Using the cost of these three discs the cost is between $2.00 and $8.00 per square meter. You do not need to use any toxic chemical stripper. With some very hard lead paint the HDSD may only strip about 2 sq meters in about an hour (worst case scenario) but that works out at around $8.50 per square meter. Stripper alone can cost between $30 -$40 per square meter, excluding application time, and then you still have to scrape it off!! Note that all surfaces are different and these cost figures are indicative only but fairly represent achievable results providing the machine is used correctly. Again the real saving is in time. The flexible Heavy Duty Stripping disc will remove the paint at a rate of 1 square meter every 6 to 10 minutes for soft lead and 10 to 20 minutes for hard lead. No other method comes close to this.

| Summary | Alderson Sander | Dry Sanding | Tungsten + Dry Sanding |

|---|---|---|---|

| Acrylic Disc Cost | 3 to 5 cents per lm | 36 cents to $1.80 per lm | Not Applicable |

| Acrylic Sanding Time | 3 seconds per lm | 36 seconds per lm | Not Applicable |

| Paint Stripping Disc Cost | 30 cents to $0.6 per lm | Not Applicable | |

| Paint Stripping Time | 1 minute per lm | Not Applicable | 6 minutes per lm (based on two coats of stripper, wash-down & dry sand) |

Warranty

The machine is supplied with a 1 year full engine replacement warranty subject to certain conditions:

Servicing The Machine

The electric machines do not require servicing. Their bearings will eventually wear out over time and can easily be replaced.